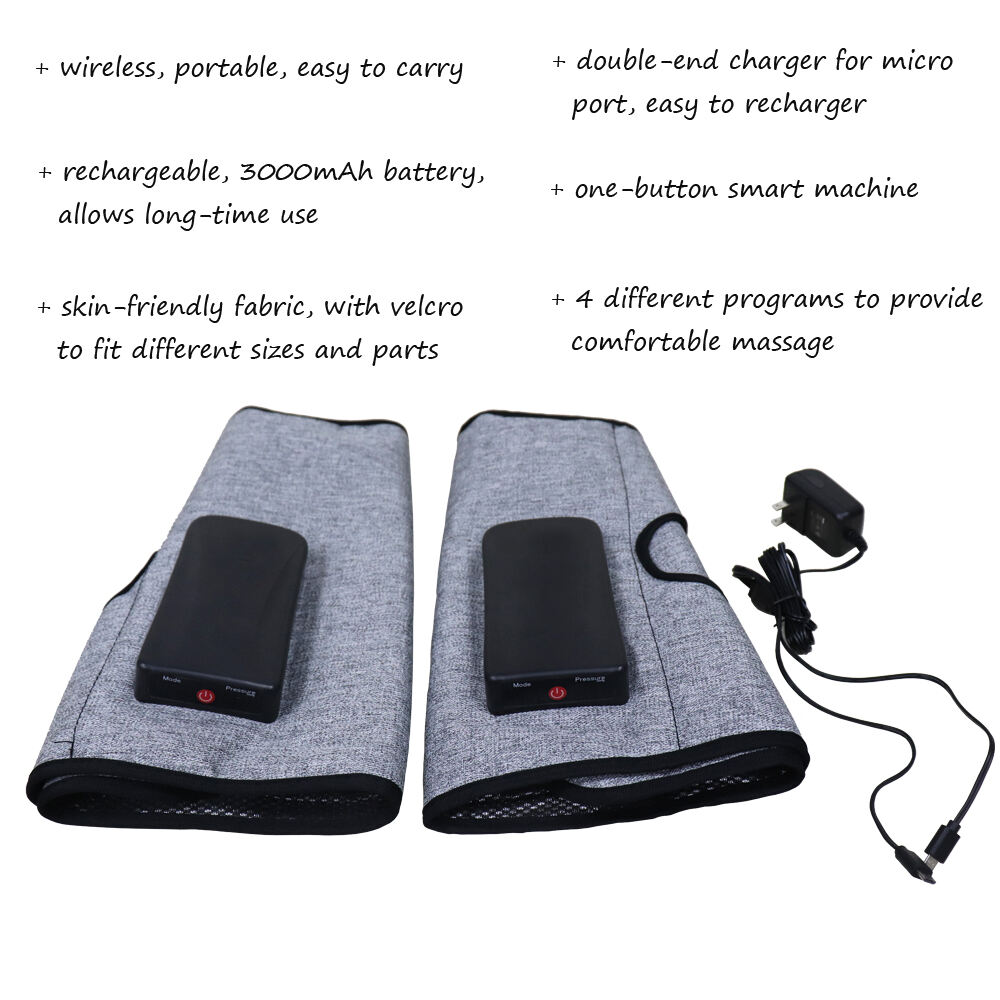

dvt pump sleeves

DVT pump sleeves represent a crucial advancement in medical technology designed to prevent deep vein thrombosis through controlled compression therapy. These innovative devices consist of specialized inflatable garments that wrap around the legs, connected to an advanced pneumatic pump system. The sleeves are engineered with multiple air chambers that inflate and deflate sequentially, creating a gentle massaging effect that promotes blood circulation in the lower extremities. The technology employs precisely calibrated pressure levels to enhance venous return and prevent blood pooling, which is essential for patients at risk of developing blood clots. Modern DVT pump sleeves feature lightweight, breathable materials that ensure patient comfort during extended wear periods. The systems typically include adjustable pressure settings, allowing healthcare providers to customize treatment protocols according to individual patient needs. These devices are particularly valuable in both hospital and home care settings, serving patients recovering from surgery, those with limited mobility, or individuals with circulatory disorders. The sleeves incorporate advanced sensors that monitor pressure distribution and maintain consistent compression levels throughout the treatment cycle. With user-friendly interfaces and quiet operation, these devices enable effective prophylactic treatment while minimizing disruption to daily activities or rest periods.